OEM/ODM Supplier Aluminium Coated Steel Sheet - G330 Hot Dip Gi Galvanized Steel Sheet – Zhanzhi

OEM/ODM Supplier Aluminium Coated Steel Sheet - G330 Hot Dip Gi Galvanized Steel Sheet – Zhanzhi

Feature

1.Standard: AISI, ASTM, BS, DIN, GB, JIS

2.Grade: G330, all according to the customer’s request

3.Standard: JIS3321/ASTM A792M

4.Thickness: 0.16mm-2.5mm, all available

5.Width: customized

6. Length: according to per customer’s requirement

7.zinc coating: 30-275g/m2

8.Spangle: zero spangle, small spangle, regular spangle, big spangle

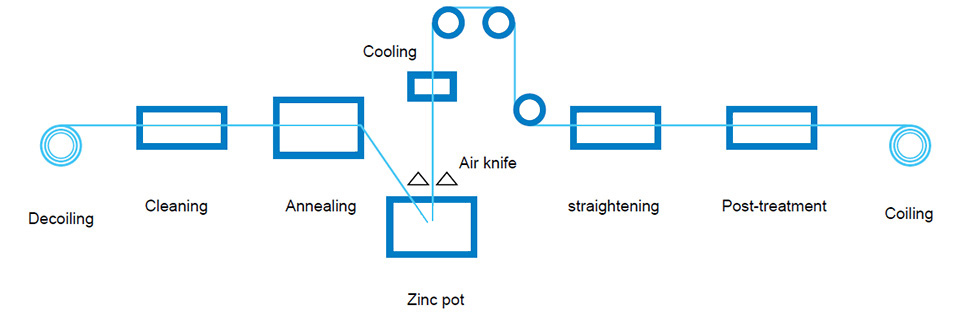

1. The cold and hot rolled steel plates are degreased by alkali washing, washed with water, dried and then annealed in a horizontal (vertical) heating furnace heated by radiant tubes, and a certain amount of hydrogen is introduced into the furnace to reduce the atmosphere in the furnace.

2. The steel strip heated to a certain temperature is immersed in zinc liquid for hot galvanizing under certain conditions.

3. The size of zinc flower is controlled by the composition of liquid zinc. At the same time, the forced cooling method is adopted. Before the zinc flower begins to spread, the small zinc flower products are rapidly cooled by small zinc flower equipment to prevent the zinc liquid from continuing to spread and form small zinc flower.

4. After hot dip galvanizing, after waiting for post cooling, finish the surface. Finally, according to the application, carry out surface passivation treatment respectively or directly produce the color coated coil board.

The surface oxidation resistance of galvanized steel sheet is strong, which can strengthen the anti-corrosion penetration ability of parts.

1. Low processing cost.

2. It is durable.

3. The durability of the coating is reliable.

4. The coating has strong toughness.

5. Every part of the plated parts can be plated with zinc, which can be fully protected even in depressions, sharp corners and hidden places.

6. The galvanizing process is faster than other coating construction methods, and the time required for painting on the construction site after installation can be avoided.

7. In general, the cost of hot dip zinc is lower than that of applying other protective coatings.

8. The inspection is simple and convenient: the hot dip zinc layer can be tested visually and by a simple nondestructive coating thickness table.

1.Buildings: roofs, walls, garages, soundproof walls, pipes and modular houses, etc.

2.Automobile: muffler, exhaust pipe, wiper accessories, fuel tank, truck box, etc.

3.Household appliances: refrigerator backboard, gas stove, air conditioner, electronic microwave oven, LCD frame, CRT explosion-proof belt, LED backlight, electrical cabinet, etc.

4.Agricultural use: pig house, chicken house, granary, greenhouse pipe, etc.

5.Others: heat insulation cover, heat exchanger, dryer, water heater, etc.

Application

As China metal materials industry leading enterprises, the national steel trade and logistics "Hundred good faith enterprise",China steel trade enterprises, "Top 100 private enterprises in Shanghai”. Shanghai Zhanzhi industry Group Co., Ltd.,(shorted to Zhanzhi Group) takes the" Integrity, Practicality, Innovation, Win-Win " as its sole operation principle, always persist in putting the customer demand in the first place.

- INTEGRITY

- WIN-WIN

- PRAGMATIC

- INNOVATION