OEM/ODM China Crgo - CRNGO Cold rolled non-oriented silicon steel coil – Zhanzhi

OEM/ODM China Crgo - CRNGO Cold rolled non-oriented silicon steel coil – Zhanzhi

Feature

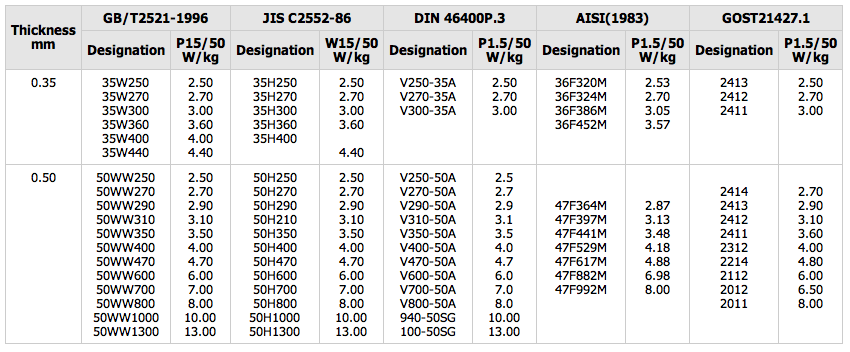

1.Standard: AISI, ASTM, BS, DIN, GB, JIS

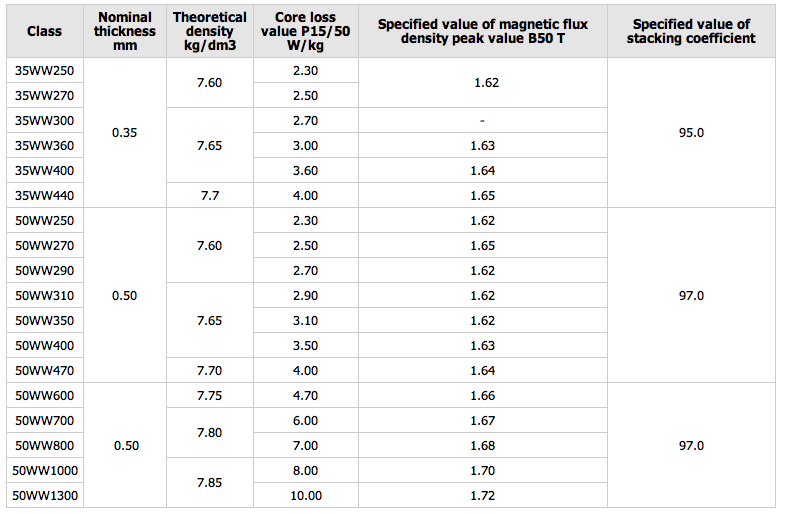

2.Grade: 35w250, 35w270, 35w300, etc.

3.Width: 600-1250mm

4.Thickness: 0.35mm, 0.50mm, 0.65mm

5.Length: as per customer’s requirement

1, low iron loss. The most important index of quality, all countries in the world divide the grades by the value of iron loss. The lower the iron loss, the higher the grade and the higher the quality. 2, high magnetic induction intensity. Silicon steel sheets with higher magnetic induction can be obtained under the same magnetic field, and the iron core of motor or transformer manufactured with it has smaller volume and weight, which can save silicon steel sheets, copper wires and insulating materials relatively.

3, high stacking coefficient. The surface of silicon steel sheet is smooth, flat and even in thickness, and the stacking coefficient of manufactured iron core is improved.

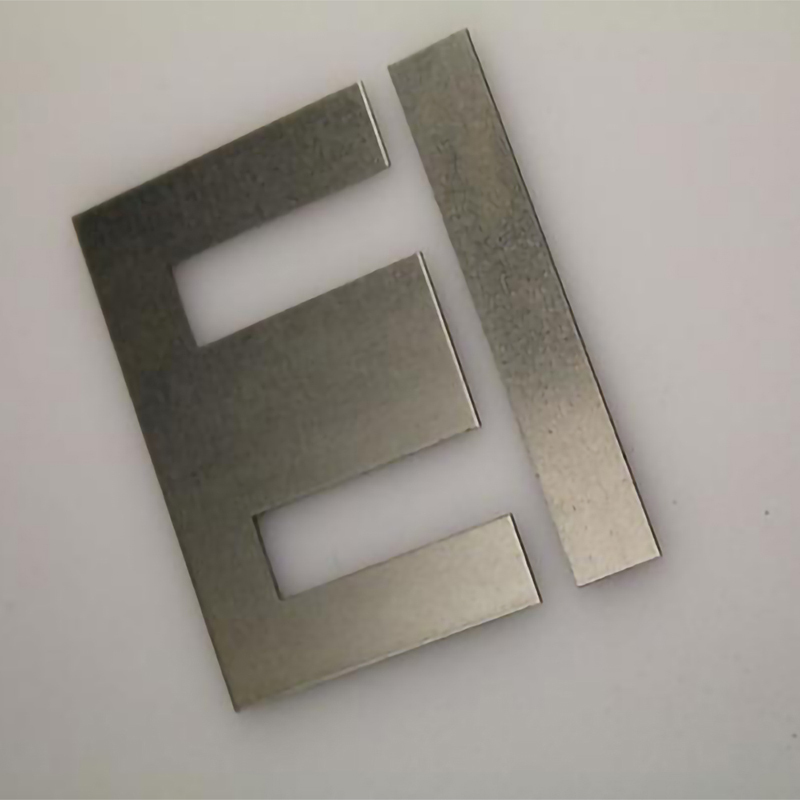

4, good stamping performance. This is more important for manufacturing small and micro motor cores.

5, the adhesion and weldability of the surface to the insulating film are good, which can prevent corrosion and improve punching property. F, magnetic aging phenomenon is small g, silicon steel sheet must be delivered after annealing and pickling.

The main purpose of cold-rolled non-oriented silicon steel sheet is to manufacture generators, therefore, it is also called cold-rolled motor silicon steel.

Application

As China metal materials industry leading enterprises, the national steel trade and logistics "Hundred good faith enterprise",China steel trade enterprises, "Top 100 private enterprises in Shanghai”. Shanghai Zhanzhi industry Group Co., Ltd.,(shorted to Zhanzhi Group) takes the" Integrity, Practicality, Innovation, Win-Win " as its sole operation principle, always persist in putting the customer demand in the first place.

- INTEGRITY

- WIN-WIN

- PRAGMATIC

- INNOVATION