What is prepainted color steel coil?

Product Definition

Prepainted steel coil is a product made of hot dip galvanized steel , hot dip galvalume steel, electro galvanized steel, etc., which is coated with one or several layers Of natural coating on the surface after surface pretreatment (chemical degreasing and chemical conversion treatment), after which cured with the aid of baking. It is named after the color coated steel coil with various colors of organic coatings, and is referred to as pre painted steel coil.

Product Features

Prepainted coils are lightweight and beautiful, have good corrosion resistance, and can be directly processed. They provide a new type of raw material for the construction industry, shipbuilding industry, vehicle manufacturing industry, home appliance industry, electrical industry, etc.

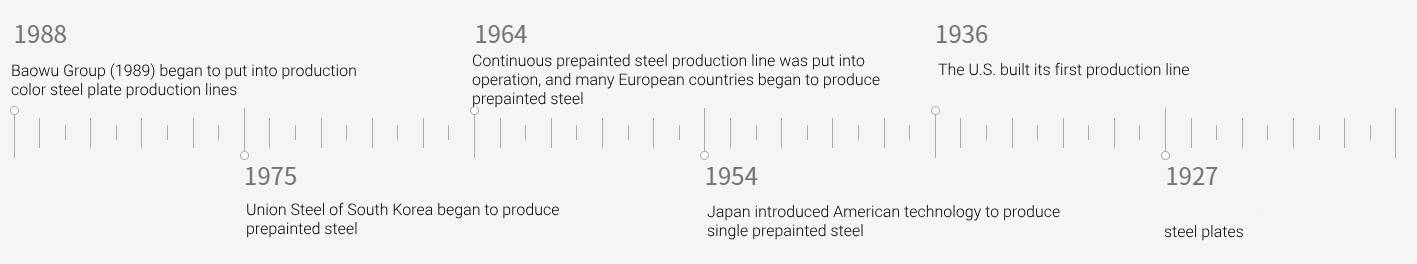

Development History Of Pre painted Coil Steel

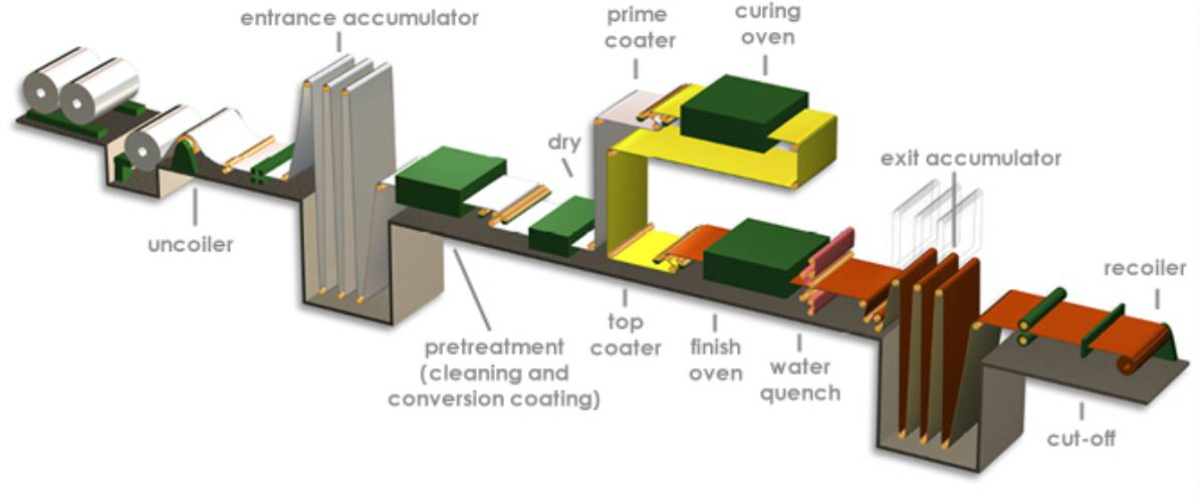

Production Process Of Prepainted Steel Coil

There are many production processes for prepainted colour coated steel coils. The most commonly used process is the traditional roller coating + baking process. Since most coatings for construction are twice-coated, the traditional two-coating and two-baking process is the most typical color coating produc tion process. The main processes of the color coating unit include pretreatment, coating, and baking.

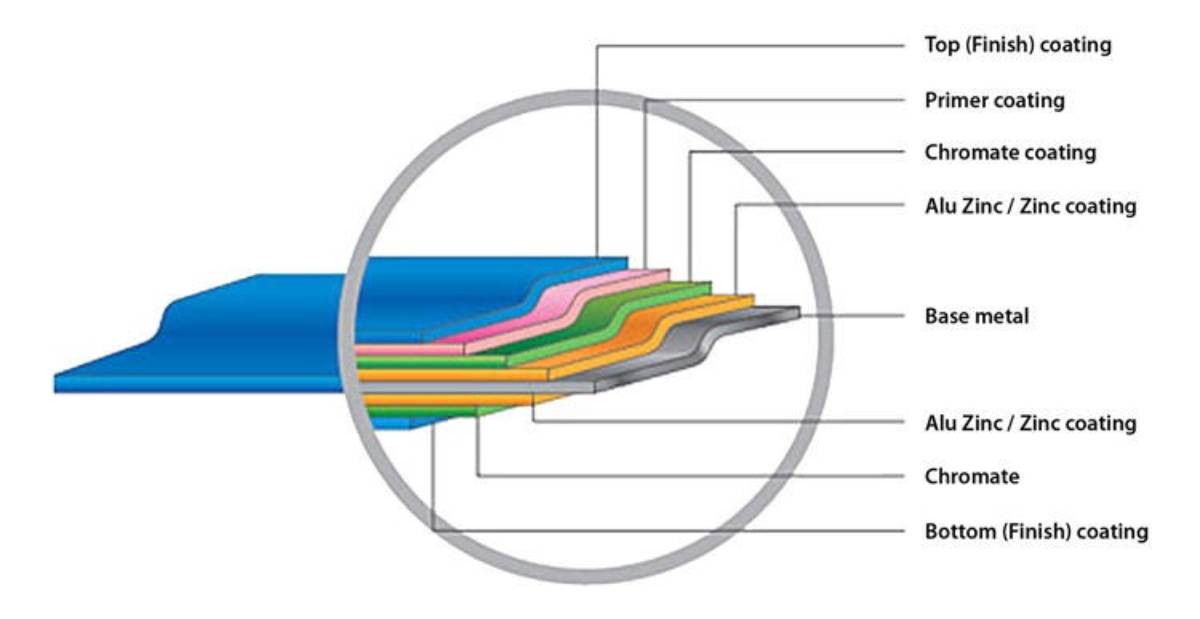

Structure of Prepainted Steel

1)Top coating: shields sunlight and prevents ultraviolet rays from damaging the coating; when the topcoat reaches the specified thickness, it can form a dense shielding coating film, reducing water permeability and oxygen permeability

Primer coating: helps to strengthen the adhesion to the substrate, making it less likely for the paint to desorb after the paint film is permeated with water, and also improves corrosion resistance, because the primer contains corrosion-inhibiting pigments, such as chromate pigments, which passivate the anode and improve corrosion resistance

2)Chemical conversion layer: improves the adhesion between the plate (galvanized, galvalume, zn-al-mg, etc.) and the coating (paint)

3)Metallic coating: generally zinc coating, aluzinc coating and zinc aluminum magnesium coating, which has the greatest impact on the service life of the product. The thicker the metallic coating, the higher the corrosion resistance.

4)Base metal: cold rolled plate is used, and different properties determine the performance of the color plate, such as strength

5)Bottom coating: prevents the steel plate from corroding from the inside, generally a two-layer structure (2/1M or 2/2 primer coating + bottom coating), if used as a composite plate, it is recommended to use a single-layer structure (2/1)

Paint Brand

Choosing a good paint brand, provides better durability and corrosion resistance

Sherwin Williams

Valspar

Akzo Nobel

Nippon

Beckers

Why Choose Us?

01

Fast Delivery Time

02

Stable Product Quality

03

Flexible Payment Methods

04

One-stop Production, Processing And Transportation Services

05

Excellent Pre-sales And After-sales Services

All You Need To Do Is Find A Reliable Manufacturer Like Us

Post time: Oct-16-2024