What are the common quality inspection methods for galvanized steel wire?

The quality inspection methods of galvanized steel wire mainly include the following:

1. Appearance inspection

Visual inspection: Check the uniformity, glossiness and presence of defects such as bubbles, cracks, and peeling of the zinc coating on the galvanized high carbon steel wire.

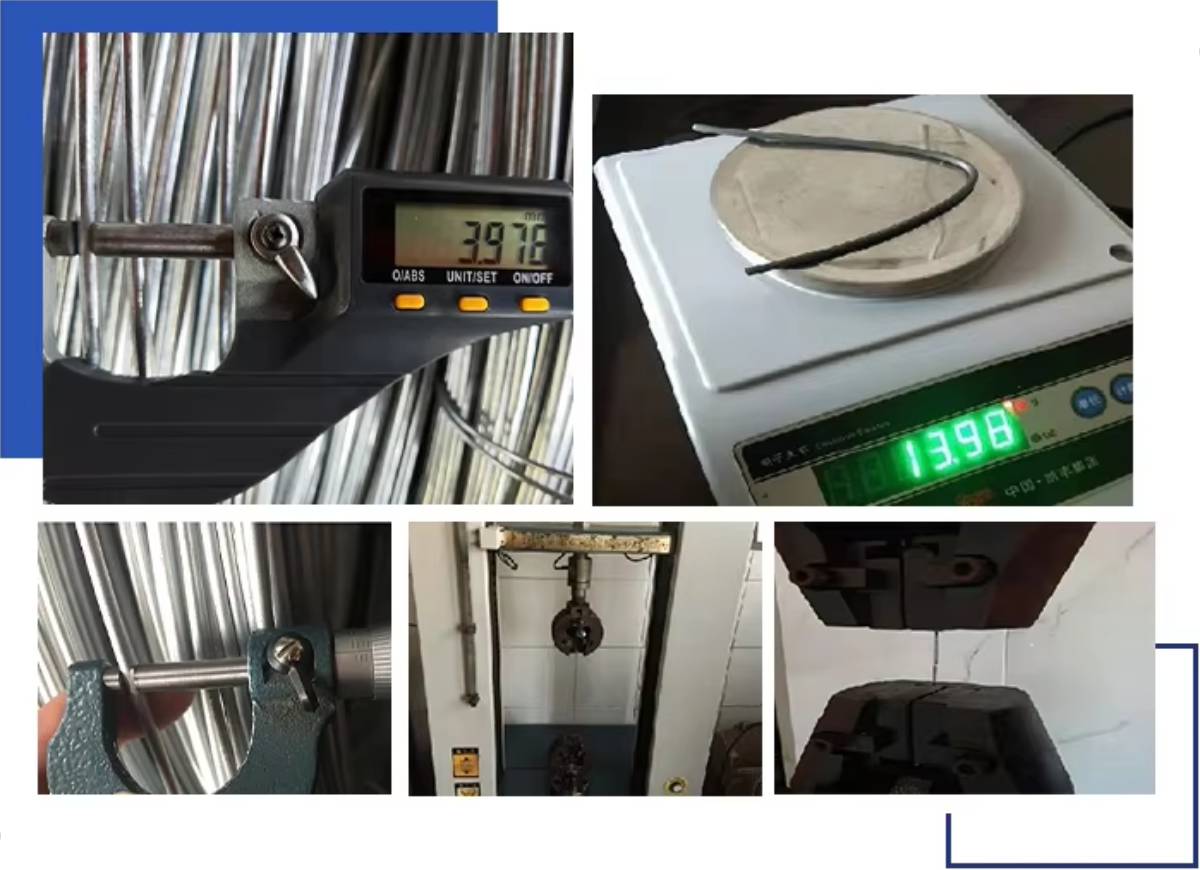

2. Coating thickness measurement

Coating thickness gauge: Use a coating thickness gauge (such as a magnetic or eddy current thickness gauge) to measure the thickness of the zinc coating on the galvanized hard drawn steel wire to ensure that it meets the standard requirements.

3. Adhesion test

Grid method: Draw a grid on the zinc coating of the galvanized thick steel wire, then tape it and quickly tear it off to check if the coating is peeling off.

Pull-out test: The adhesion of the coating of pvc coated gi wire to the substrate is tested by applying a tensile force.

4. Corrosion resistance test

Salt spray test: Put the galvanized gi fencing wire into a salt spray test chamber to simulate the corrosive environment and observe the corrosion resistance of the coating.

Immersion test: Soak the galvanized steel wire in a specific corrosive medium to evaluate its corrosion resistance.

5. Chemical composition analysis

Spectral analysis: Analyze the chemical composition of the galvanized layer through a spectrometer to ensure that the zinc content and other elements meet the standards.

The chemical composition of the galvanized layer of gi wire size 2.5mm is analyzed by spectrometer to ensure that the zinc content and other elements meet the standards.

6. Mechanical properties test

Tensile test: Test the tensile strength and elongation of the steel wire to ensure that its mechanical properties meet the requirements.

Bending test: Test the toughness and plasticity of the steel wire during bending.

7. Hardness test

Rockwell hardness or Vickers hardness test: Measure the hardness of the galvanized steel wire to evaluate its wear resistance.

Through the above-mentioned various testing methods, the product quality of different galvanized steel wire rope manufacturers can be comprehensively evaluated to ensure their performance and safety in practical applications.

Why Choose Us?

01

Fast Delivery Time

02

Stable Product Quality

03

Flexible Payment Methods

04

One-stop Production, Processing And Transportation Services

05

Excellent Pre-sales And After-sales Services

All You Need To Do Is Find A Reliable Manufacturer Like Us

Post time: Dec-11-2024