Do you know how to detect the surface quality of hot rolled steel coils?

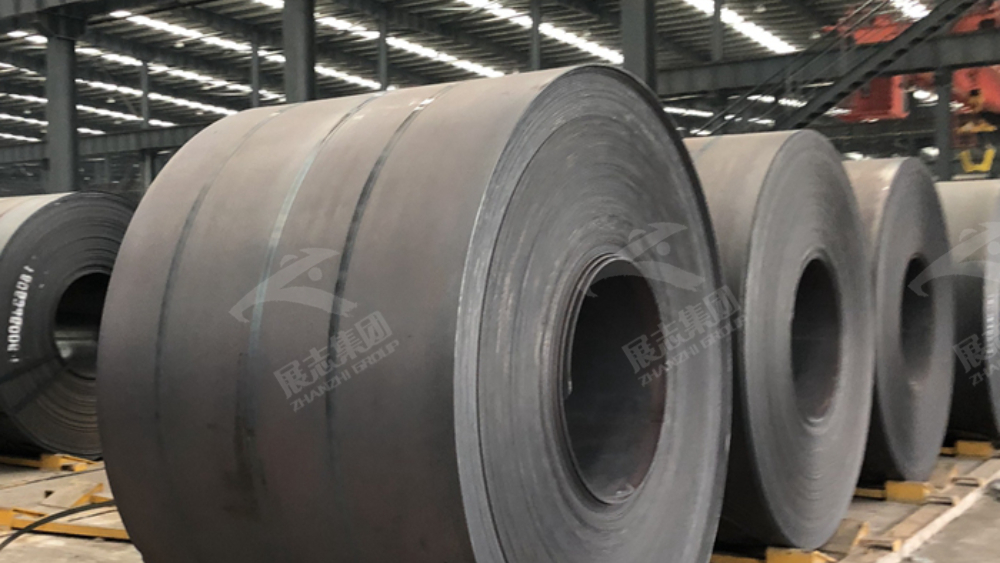

For hot-rolled steel coils, the key factor that determines product quality is its surface condition. To ensure that the surface is free of blemishes and blemishes, rigorous testing techniques are employed. The purpose of this article is to elucidate the testing techniques used to evaluate the surface quality of ms steel sheet rolled coil hot and to highlight its importance in providing a quality product.

One of the inspection techniques commonly used to evaluate the surface quality of prime quality hot rolled steel sheet in coil is visual inspection. Skilled technicians carefully inspect the surface of the coil to identify any visible defects such as scratches, scuffs, or rust. Through visual inspection, they can determine the severity of the defect and determine the appropriate measures needed to correct it.

In addition to visual inspection, another testing technique worth noting is magnetic particle inspection. This non-destructive technique is particularly useful for detecting surface cracks and defects that are not easily visible to the naked eye. By applying a magnetic field to the hot rolled steel sheet in coils a36, technicians can observe the pattern of magnetic particles to identify any anomalies on the surface. This technology ensures that even the smallest defects are detected, resulting in the production of high-quality hot rolled steel coil a36.

Ultrasonic testing is also used to check the surface quality of hot rolled steel coils. The technology uses high-frequency sound waves to penetrate materials and detect internal defects. By scanning the coil surface with an ultrasonic probe, technicians can identify any hidden flaws or inconsistencies in the steel structure. This technology improves the overall quality and integrity of the coil, assuring customers of its reliability and durability.

In a highly competitive market, price becomes a crucial factor. However, it is important to remember that the lowest hot rolled steel coil price may not always guarantee quality. By ensuring that coils are extensively tested using the techniques described above, manufacturers can deliver products that meet the highest industry standards.

To sum up, the surface quality of hot-rolled steel coils plays an important role in determining the overall quality of the product. Visual inspection, magnetic particle inspection, and ultrasonic testing are some of the testing techniques used to evaluate surface condition. These technologies ensure that potential defects are detected and corrected, resulting in the production of high-quality hot-rolled steel coils. Therefore, when considering hr coil price, be sure to choose manufacturers that prioritize testing the surface quality of their products.

Post time: Dec-01-2023