High Quality For Cr Coil - CRGO Cold Rolled Silicon Steel Coil For Transformer – Zhanzhi

High Quality For Cr Coil - CRGO Cold Rolled Silicon Steel Coil For Transformer – Zhanzhi

Feature

1)Material: all available

2)Size: as per customer’s requirement

3)Surface treatment: as per customer’s requirement

4)Packing: standard sea-worthy packing

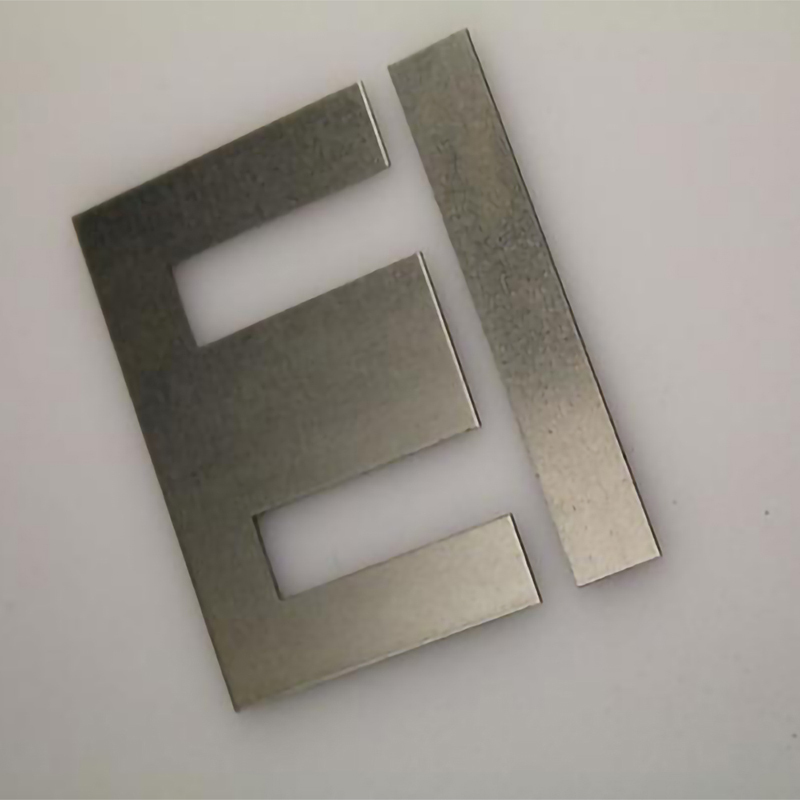

5)Processing service: cutting, decoiling, punching, etc.

Oriented silicon steel is smelted by oxygen converter. The billet is hot rolled, normalized, cold rolled, annealed in the middle and cold rolled for the second time, then decarburized and annealed at high temperature, and finally coated with insulating layer.

①Ore-②iron making-③steel making-④hot rolling-⑤pickling-⑥cold rolling-⑦annealing-⑧cold rolling silicon steel (oriented electrical steel).

Cold rolled oriented thin silicon steel strip is made by pickling, cold rolling and annealing oriented silicon steel strip with thickness of 0.30mm or 0.35mm. Cold rolled non-oriented silicon steel sheets are hot rolled into coils with a thickness of about 2.3mm from steel billets or continuous casting billets.

Cold rolled oriented thin silicon steel strip is made by pickling, cold rolling and annealing oriented silicon steel strip with thickness of 0.30mm or 0.35mm. Cold rolled non-oriented silicon steel sheets are hot rolled into coils with a thickness of about 2.3mm from steel billets or continuous casting billets.

The magnetism of oriented silicon steel has strong directionality, which has the lowest iron loss value, the highest permeability and high magnetic induction value under a certain magnetization field.

Cold rolled silicon steel has the characteristics of smooth surface, uniform thickness, high stacking coefficient and good punching property, and has higher magnetic induction and lower iron loss than hot rolled silicon steel. Using cold rolled silicon steel instead of hot rolled silicon steel to manufacture motor or transformer can reduce its weight and volume by 0%-25%. If cold rolled oriented silicon steel is used, its performance will be better. Using it instead of hot rolled silicon steel or low-grade cold rolled silicon steel can reduce the power consumption of transformer by 45%-50%, and the working performance of transformer is more reliable.

Application

As China metal materials industry leading enterprises, the national steel trade and logistics "Hundred good faith enterprise",China steel trade enterprises, "Top 100 private enterprises in Shanghai”. Shanghai Zhanzhi industry Group Co., Ltd.,(shorted to Zhanzhi Group) takes the" Integrity, Practicality, Innovation, Win-Win " as its sole operation principle, always persist in putting the customer demand in the first place.

- INTEGRITY

- WIN-WIN

- PRAGMATIC

- INNOVATION